On June 5, at the Inter Lubric China 2024,MWF & SC 2024, Ms. Huang Yingmei, a reporter from LUBRICANT GUIDEBOOK , came to the booth of Francool Technology (SZ) Corp.,Ltd. and interviewed Mr. Fan Chengli, Chairman of Francool Technology (SZ) Corp.,Ltd., to explore Francool's future development direction and the thoughts of this national enterprise pioneer on the metalworking fluid industry.

*Mr. Fan Chengli, Chairman of Francool Technology (SZ) Corp.,Ltd., was interviewed by the reporter of LUBRICANT GUIDEBOOK

01 Focus on layout and take the fast track of new energy development

Francool Technology (SZ) Corp.,Ltd. (hereinafter referred to as "Francool") was established in 2001 and is headquartered in Shenzhen, China. It has been deeply involved in the metal and new material processing fluid segments and is a leading one-stop solution provider for metal and new material processing fluids in China. Products mainly include metal and new material processing fluids, rolling fluids, release agents, high-end rail transit and aviation special oils and synthetic automotive oils, environmental protection technology, and automated industrial equipment.

After more than 20 years of development and accumulation, Francool has a total of 8 registered wholly-owned subsidiaries at home and abroad, and its offices and sales networks radiate to 25 cities or regions in China.

It is understood that Francool has reached in-depth cooperation with well-known domestic and foreign companies such as AVIC, China North Industries Group, SAIC-GM, Dongfeng, Great Wall, Geely, BYD, King Long, Jiangling, Dalian FAW-Volkswagen, Kohler, ZF, AAC, Tongda, Foxconn and Samsung Electronics. Its customers are in many fields such as 3C, automobile, aerospace, military industry, steel, etc., and it also has important overseas partners in Germany, South Korea and Japan.

The vigorous development of domestic and foreign markets has brought more possibilities for Francool. When mentioning Francool's key layout, Chairman Fan Chengli revealed: "In terms of product focus, Francool will mainly focus on the layout of the integrated die-casting sector of new energy vehicles in the future; in terms of market areas, it will explore Thailand, Mexico, Czech Republic, Hungary and other European countries in the future. Among them, Mexico is the country we will focus on this year, and the European market is also the area that Francool will focus on expanding in the next two years."

According to the "Energy-Saving and New Energy Vehicle Technology Roadmap"《节能与新能源汽车技术路线图》released by the China Society of Automotive Engineers, by 2030, Chinese cars should achieve a 40% weight reduction. Integrated die-casting, as an important process, has become a trend in the development of lightweight automobiles. Since Tesla first applied integrated die-casting technology to the Model Y, domestic new car manufacturers have quickly followed up in the past two years, and some traditional car companies have also made layouts or plans to varying degrees. The policy has set the tone for development, and the pace of integrated die-casting industrialization has continued to accelerate.

Based on this background, Chairman Fan Chengli mentioned that when domestic new energy vehicle manufacturers are focusing on the development of integrated die-casting technology, the release agent, cleaning agent and other products at the back end of new energy vehicle processing have great market potential, which is also the industry that Francool will focus on in the future.

02 New product launch, 7030T series bio-based synthetic cutting fluid

As a metalworking fluid company recognized as strong in the industry, Francool has always kept up with the pace of changes in metal and new material technology, and constantly innovated its own products.

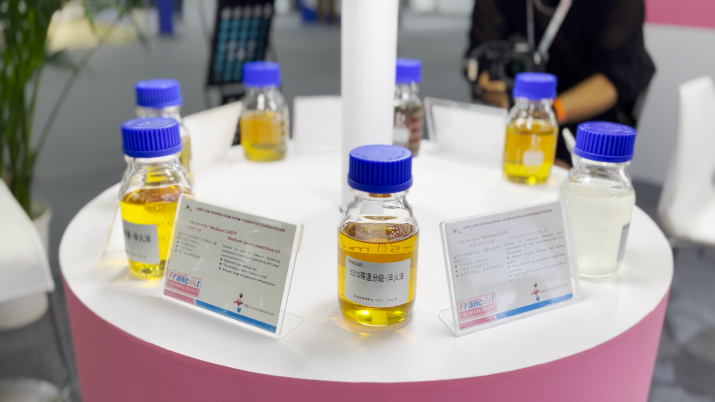

According to LUBRICANT GUIDEBOOK, in response to the pain points of machine tool customers, Francool has focused on launching a new self-developed [7030T series bio-based synthetic cutting fluid] this year to solve a series of problems such as large usage of machine tool customers, easy wear of tools, poor workshop environment and environmental protection requirements.

Chairman Fan Chengli introduced to LUBRICANT GUIDEBOOK: "[7030T Series Bio-based Synthetic Cutting Fluid] is our recently launched low-carbon, environmentally friendly and biodegradable product. Its main features are that it does not contain mineral oil or fungicides, and its lubrication performance is very high. It performs very well in terms of both service life and biodegradability. In terms of biodegradability, it only takes 35 days for 7030T to be completely degraded, and its carbon emissions over the entire life cycle are reduced by 80% compared with other similar products. In terms of hard water resistance, 7030T's hard water resistance reaches more than 1,000ppm. In terms of long-term use, 7030T's hard water resistance can make it stand out."

FRANCOOL 7030T series product features:

lNo mineral oil, very small emulsion particle size, stable emulsion;

lLubrication performance improved by about 30%;

lEnvironmentally friendly, no boron, chlorine, nitrite, formaldehyde, DCHA;

lLow odor, mixed with water to form a slightly transparent stable liquid;

lHas better biological stability, and has good lubrication, extreme pressure and cooling properties.

Regarding the new product, Chairman Fan Chengli added: "It has been nearly two years since the product was developed and released. At present, customer feedback shows that in the use scenario, both the odor and other performance aspects are better than traditional cutting fluid products."

With the increasing global attention to environmental protection, the development of metalworking fluids has tended to be more environmentally friendly, including reducing the use of volatile organic compounds and harmful chemicals, using biodegradable ingredients, and more effective waste fluid treatment methods. As a pioneer in the industry in proposing the concept of low-carbon cutting fluid, Francool has also been earnestly implementing the goal of dual carbon emission reduction, constantly innovating and creating more green and environmentally friendly products; integrating knowledge and action, standing at the forefront of industry development.

03 Technological innovation, domestic substitution is just in time

As the hidden champion of the local cutting fluid industry and one of the largest metalworking fluid manufacturers in China, Francool's domestic and foreign products currently have a growing global market share year by year. With its advantages of strong product technology, large production scale and stable supply chain, Francool is favored by domestic companies.

In addition, Francool also participated in the formulation of industry standards for metalworking fluids, mastered the core technology of the industry that is not behind that of Western countries, and independently developed and produced high-end metalworking fluids, water-soluble cutting fluids and other products with world-leading quality. At present, its product market share is gradually on par with major foreign brands.

In 2022, many of Francool's cutting fluid products passed the localization technology research and appraisal of large state-owned enterprises in the aviation field, breaking the long-term monopoly of foreign brands in this field and opening up the situation for domestic substitution.

Talking about the situation of domestic substitution of imported metalworking fluids, Chairman Fan Chengli said: "The Chinese metalworking fluid industry has experienced rapid development and improvement in the past few decades and has gradually become a competitive industry. Five years ago, in the field of high-end special equipment, especially in the aviation and automotive industries, imported products accounted for 90% of the market. Now the market for domestic products is expanding step by step. As far as I know, domestic metalworking fluid companies are working hard to narrow the gap with foreign products; we are the same at Francool, working hard for better products and better development."

"I think that in the next few years, the domestic substitution of metalworking fluids will gradually catch up in terms of technology. At present, domestic products have made great progress, and some products can even surpass imported products, which is something the domestic metalworking fluid industry can be proud of. In particular, some domestic additive manufacturers, such as Guangzhou Mickey Chemical Co., Ltd., have achieved a lot of domestic substitution in additives, which is of great significance to the development of the metalworking fluid industry. So we are confident that in the near future, the metalworking fluid industry will be able to achieve large-scale domestic substitution. "

In the future, Francool will continue to make efforts to combine innovation with actual production, adhere to the investment in research and development and innovation, and strive to establish more and stronger cooperation with central enterprises and state-owned enterprises. On the one hand, further promote the process of product serialization, continuously develop metalworking fluids with long service life, good performance, safety and environmental protection, and promote the realization of carbon peak and carbon neutrality; on the other hand, keep up with the demand for domestic substitution in the high-end metal processing market, focus on increasing the development of high-precision, high-efficiency and high-stability high-end products, seek breakthroughs in key high-end manufacturing fields such as aerospace, rail transportation, and military industry, and strive to solve the "stuck neck" problem as soon as possible and realize the localization of core technologies and key consumables. At the same time, we will also increase brand building, enrich product levels, establish a production base in Southeast Asia, and continue to expand to the European and American markets.

Postscript

As an important part of the petrochemical industry, a national pillar industry, the metalworking fluid industry is closely related to the national macro-situation and the development of the automotive, machinery, 3C, shipbuilding, aerospace, railway, medical and other industries.

In recent years, with the introduction of various favorable policies, China's metalworking fluid industry production technology has continued to break through, and environmentally friendly cutting fluids with good performance and long life have gradually become the mainstream of the market. "Lubricant Shopping Guide" believes that under the demand for green, low-carbon and high-end substitution, Francool will continue to work hard on innovation and research and development, and will surely achieve leapfrog development in the near future, driving the industry's localization space to further increase!

*Mr. Fan Chengli, Chairman of Francool Technology (SZ) Corp.,Ltd., and Ms. Huang Yingmei, a reporter of LUBRICANT GUIDEBOOK