21st Guangzhou International Textile, Clothing and Printing Industry Expo

Exhibition News

On the vast land of Central Asia, Uzbekistan shines like a bright pearl. Endowed with its unique geographical location and abundant resources, it radiates dazzling brilliance in the textile and garment sector. Recently, the organizing committee team of ITCPE Guangzhou conducted in-depth visits to a number of local textile and garment enterprises. This trip allowed the team to explore the vigorous vitality and boundless potential of Uzbekistan's textile and garment industry, and also witness the new opportunities that ITCPE Guangzhou is about to bring to this thriving industrial land.

01 Solid Industrial Foundation and Broad Development Prospects

Uzbekistan is located at the heart of Central Asia and the ancient Silk Road. With a population of 35 million, accounting for 65% of the total population in Central Asia, it has become the largest consumer market for textiles, apparel, underwear, footwear and accessories in the region. This massive consumer base provides solid market support for the textile and garment industry.

Meanwhile, Uzbekistan is also the world's fifth-largest cotton-producing country, with an average annual output of 3.5-3.7 million tons of seed cotton, which can be processed into 100,000-120,000 tons of lint cotton. Its abundant cotton resources provide high-quality and sufficient raw materials for the textile and garment industry, reducing production costs and enhancing industrial competitiveness.

Currently, Uzbekistan is home to over 900 textile mills and more than 1,000 garment processing enterprises. Every year, dozens of new cotton spinning, cotton weaving and ready-to-wear manufacturing plants are established, and this growth trend is expected to continue over the next five years. As a result, the industry scale is constantly expanding, showing a highly robust development momentum.

02 Visiting Enterprises: Gaining Insights into Industry Status Quo and Innovation Vitality

During this visit, we gained in-depth insights into a number of representative textile and garment enterprises. Each of these enterprises has its own distinctive features, collectively presenting the diversified development pattern of the local industry.

Stampa textile

It is a forward-looking enterprise deeply engaged in the textile printing industry, equipped with advanced production equipment. The factory also has a complete production line, and every link—from raw material preparation to final printing—is under strict quality control.

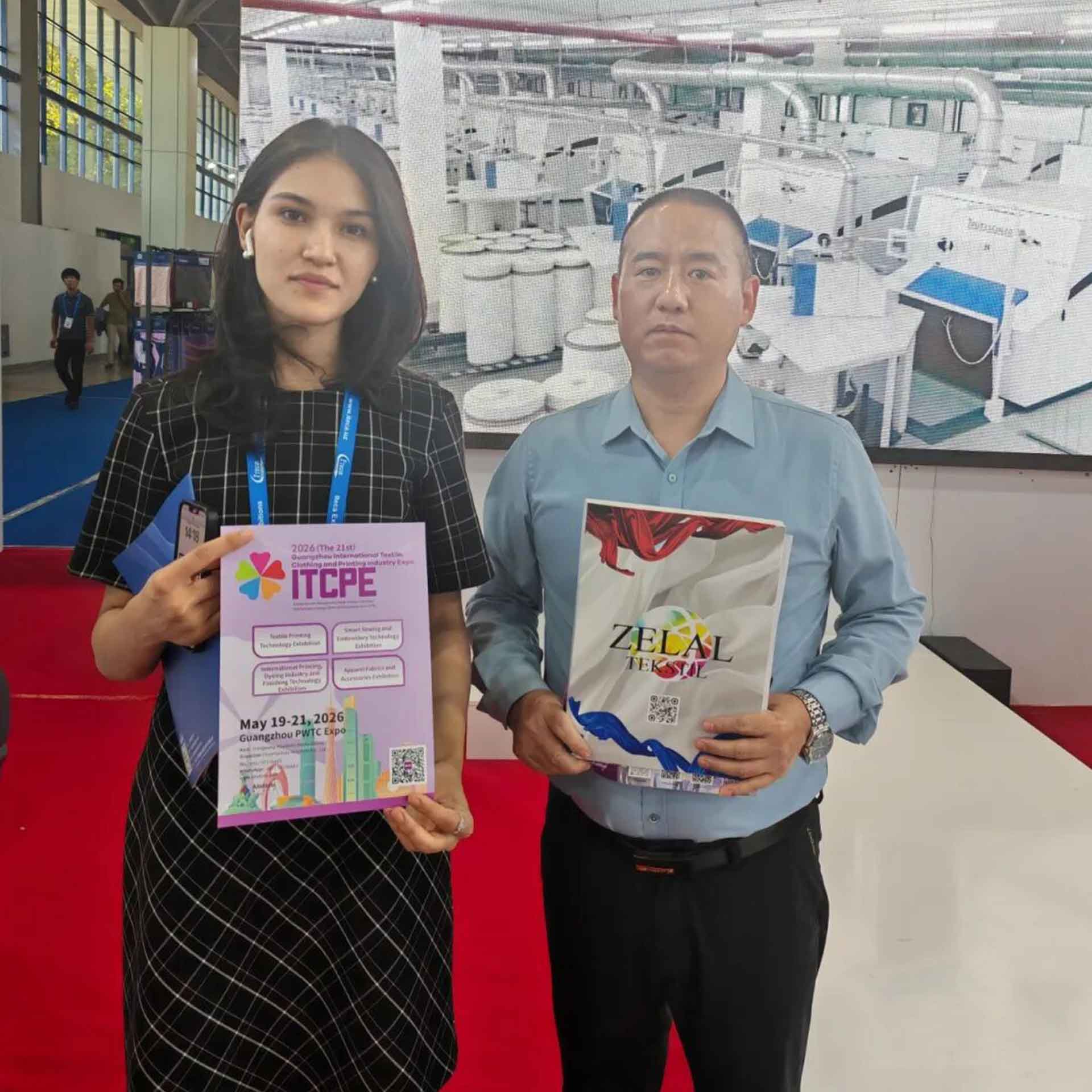

Zelal Tekstil LLC

It is a Sino-Uzbek joint venture textile company established by a Turkish enterprise and a local Uzbek enterprise, mainly engaged in knitting, dyeing and printing businesses. The company adopts advanced dyeing and printing equipment from Turkey and Italy, including dyeing equipment, flat screen printing equipment, rotary screen printing equipment, as well as high-end Italian MS digital printing machines. Its strict quality control system implements three-stage strict supervision from raw material procurement to finished product delivery, ensuring the excellent quality of products. Meanwhile, the company's products are sold far to Central Asian regions, Europe and the United States, and have strong competitiveness in the international market.

ART PRINT AND TEXTILE

As a ready-to-wear manufacturing factory located in Tashkent, it specializes in producing corporate uniforms for various industries. Equipped with a complete production line, it integrates development, production and sales. It also covers a full range of processing procedures including printing, embroidery, heat transfer printing and sewing, which demonstrates its professionalism and comprehensiveness in the ready-to-wear manufacturing field.

Bek Mega Textile

It is a modern knitting production enterprise, with highly automated dyeing and printing facilities as one of its major highlights. Its dyeing process complies with European standards, featuring strong color consistency and low defect rates. The printing equipment is capable of presenting realistic and rich colors, while the fabrics produced are soft in texture and wear-resistant. Most of the company's production equipment is sourced from Turkey and Italy; its workshops are neat and clean, with distinct management characteristics. As the industrial decentralization of Tashkent progresses, the area of the company's self-built factory on the outskirts will double. In the future, it will also move toward digitalization in printing and dyeing, demonstrating the enterprise's pursuit of technological innovation and sustainable development.

Factory Tour

Uztex Tashkent LLC

It is the latest vertically integrated textile enterprise in Central Asia, covering the entire industrial chain from spinning, knitting, dyeing, printing to ready-to-wear sewing. The company adopts advanced equipment from Switzerland and Japan, and implements high-standard control in processes and quality. It also has clothing sales and design stores in downtown Tashkent, realizing integrated operations from production to sales and providing more convenient services for consumers.

CLASSTEX Production

It is a printing and dyeing enterprise with strong strength. Its dyeing and finishing factory has an independent color laboratory, which can develop complex color formulas according to customer needs. The company is mainly engaged in dyeing, printing and textile production, providing customers with full-process services. It can produce over 150 tons of dyed fabrics and 300 tons of printed fabrics per month, adopting steel roller mold printing. At the same time, it is considering introducing digital printing equipment to leverage the cost advantages and equipment stability of digital printing to improve production efficiency and product quality.

Through visiting these enterprises, we learned that in addition to traditional printing, some local textile printing and dyeing enterprises have already adopted digital printing technology. And as digital printing technology and equipment become more mature, an increasing number of enterprises will adopt digital printing technology. Meanwhile, we also found that most of their equipment is imported from Italy, which comes with high costs—this has hindered the development of digital printing to a certain extent. As an important event in the textile and garment industry, ITCPE Guangzhou gathers a large number of advanced textile, garment and printing technologies, equipment, processes and advanced materials from around the world. It provides enterprises with an excellent platform for communication, cooperation and market expansion.

After we introduced to the enterprises the cost advantages of China's digital printing equipment and digital printing production, many of them showed strong interest and planned to visit ITCPE Guangzhou from May 19 to 21, 2026. These enterprises look forward to learning more about textile, garment and printing technologies, equipment, processes and advanced materials at the expo, finding suitable partners, reducing production costs, and improving product quality and market competitiveness. Meanwhile, they also hope to gain insights into the latest industry developments and trends through the expo, so as to formulate more scientific strategic plans for the enterprises' future development.

The textile and garment industry in Uzbekistan is in a golden period of rapid development, and ITCPE Guangzhou provides it with an important window to connect with the global textile and garment industry. It is believed that with the joint efforts of both sides, the cooperation between China and Uzbekistan in the textile and garment field will become closer, achieving mutual benefit and win-win results, and jointly creating a bright future for the textile and garment industry. Let us jointly look forward to the wonderful exchanges and in-depth integration between Uzbek enterprises and the global textile and garment industry at the 2026 ITCPE Guangzhou.

-END-

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967