Exhibition News

What are the aspects of fabric feel?

The feel style of fabric is the common requirement of the comfort function and beautification function of clothing, and is also the basis of the formation of clothing shape and clothing style. The feel style of the fabric mainly includes the touch, hand feel, stiffness, flexibility and drape of the fabric.

Touch of fabric.

-- The touch of fabric refers to the feeling of human skin when touching the fabric.

Such as smooth, rough; Weak, pretty scrape;

Smooth, astringent plate; Active collaterals, sluggish;

Rigid and soft; Fluffy and stiff;

Thick, thin; Plump and loose;

Warm, cool, etc.

The sense of touch of fabric is related to various factors of fabric composition:

For example, different raw materials have different senses of touch, silk is smooth, hemp is rough and hard;

The same raw material fabric with different yarn count has different touch, low count cotton fabric is rough, high count cotton fabric is fine and clean.

Fabrics with different warp and weft densities have different tactile sensations, high-density fabrics are stiff, sparse fabrics are weak, etc.

Different fabric organizations have different touch, satin fabric smooth, plain fabric flat and so on;

Different finishing processes have different tactile sensations, such as smooth and soft liquid ammonia finishing, plump waxy and slippery hairy loose finishing, etc.

Feel of fabric.

--The feel of the fabric refers to the feeling of the hand to identify certain physical characteristics of the fabric, which is an important aspect of style.

Different fabrics have different feel, such as medium and thick tweed, wool-like fabrics require a full, thick feel, and valitin, cool and other thin wool fabrics require a smooth feel, quite cool.

The factors that affect the feel of fabric include fiber raw materials, yarn fineness and twist, fabric organization and dyeing and finishing process. Among them, the fiber raw materials have a greater impact, the fiber details feel soft, and the fiber is smooth. The twist of the yarn is appropriate, and the fabric feels soft and cool; If the twist is too large, the fabric feels hard; If the twist is too small, the fabric feels soft.

Hand feel is also related to some mechanical properties of the fabric, such as flexibility, extensibility, resilience and so on.

Flexibility indicates the ease of bending or stiffness of the fabric;

Extensibility indicates the degree of tensile deformation of the fabric;

Resilience indicates the degree of fabric deformation recovery.

The surface heat transfer coefficient and heat transfer rate reflect the cool or warm condition of the fabric.

The feel of the fabric reflects the appearance and comfort of the fabric to different degrees.

0

The stiffness and flexibility of the fabric.

--The rigidity and flexibility of fabric refers to the ability of fabric to resist the bending stress, also known as flexural stiffness.

The greater the flexural stiffness, the stiffer the fabric. Appropriate flexural stiffness indicates that the fabric is crisp.

The flexural stiffness of fabric is related to the properties of raw materials, the thickness of fabric fibers and the density of fabric.

Drape of fabric.

--Drape of fabric refers to the properties of fabric forming smooth and uniform curved surfaces under natural drape. The softer the fabric, the better the drape.

Drape is the performance of soft clothing style must be necessary, such as trumpet skirt hem, drooping shape and loose clothing shape, etc., all need good drape fabric.

Drape is related to stiffness and flexibility, and fabrics with high flexural stiffness have poor drape. The fabric with fine fiber and loose tissue has better drape.

Fabric feel and surface characteristics have become important factors affecting consumers' purchasing decisions. Therefore, in recent years, fabric researchers and clothing brands have strengthened the evaluation of fabric feel. The feel of fabric is the result of people's comprehensive feeling of fabric surface texture through touch, sight and hearing.

The classification and quantification of fabric surface characteristics are helpful for clothing brands and related researchers to analyze and evaluate fabric feel and find improvement solutions. With the continuous progress of science and technology, the evaluation and testing of fabric feel have gradually changed and developed from subjective to objective, and the quantitative and digital simulation technology of fabric surface characteristics has been paid attention to.

01

Prior to the study of the factors influencing textile feel, the early classification of fabric texture and feel was mainly achieved by consumers, textile manufacturers and textile researchers observing and touching the fabric. Subjective evaluation can more directly reflect people's perception of fabric texture, but the results are not accurate enough. With the development of textile manufacturing technology, using objective characterization and measurement methods to qualitatively and quantitatively test textile feel characteristics has become the main goal of researchers in the textile industry.

Since 1955, three categories of fabric feel tester have been developed: fabric fixed, test device fixed and non-contact.

The first type of tester prevents the impact of fabric curling and sliding on the results during the test. The University of Orleans, France, designed a fabric feel test device. The fabric and the standard are fixed on the upper surface and the lower surface respectively. The detection device of the fixed standard is moved under the setting parameters to measure the feel of the fabric under different conditions. However, due to the relatively uneven surface of the fabric, the fixed fabric is easy to ignore the characteristic changes of other parts of the fabric, and the stretching deformation of the fabric may also affect the experimental results.

More researchers chose to develop a second type of tester, which minimizes fabric variation by moving the fabric during the test. Researchers continue to make innovations in the development of fixed fabric feel tester for test devices, such as KES-F developed by Kawabata et al., FAST fabric simple tester developed by the Commonwealth Scientific and Industrial Research Organization, LUFHES fabric feel evaluation system developed by the University of Leeds, and FTT fabric feel tester co-developed by SDL Atlas and Hong Kong Polytechnic University. All have been put into textile inspection and testing applications.

In addition, some researchers use non-contact measurement methods to eliminate the impact of interaction on the fabric surface during contact. Studies show that non-contact measurements are more accurate, especially when it comes to measuring fabric anisotropy, but some believe that the contact method is closer to the fingertip feeling and is better for measuring fabric feel and comfort.

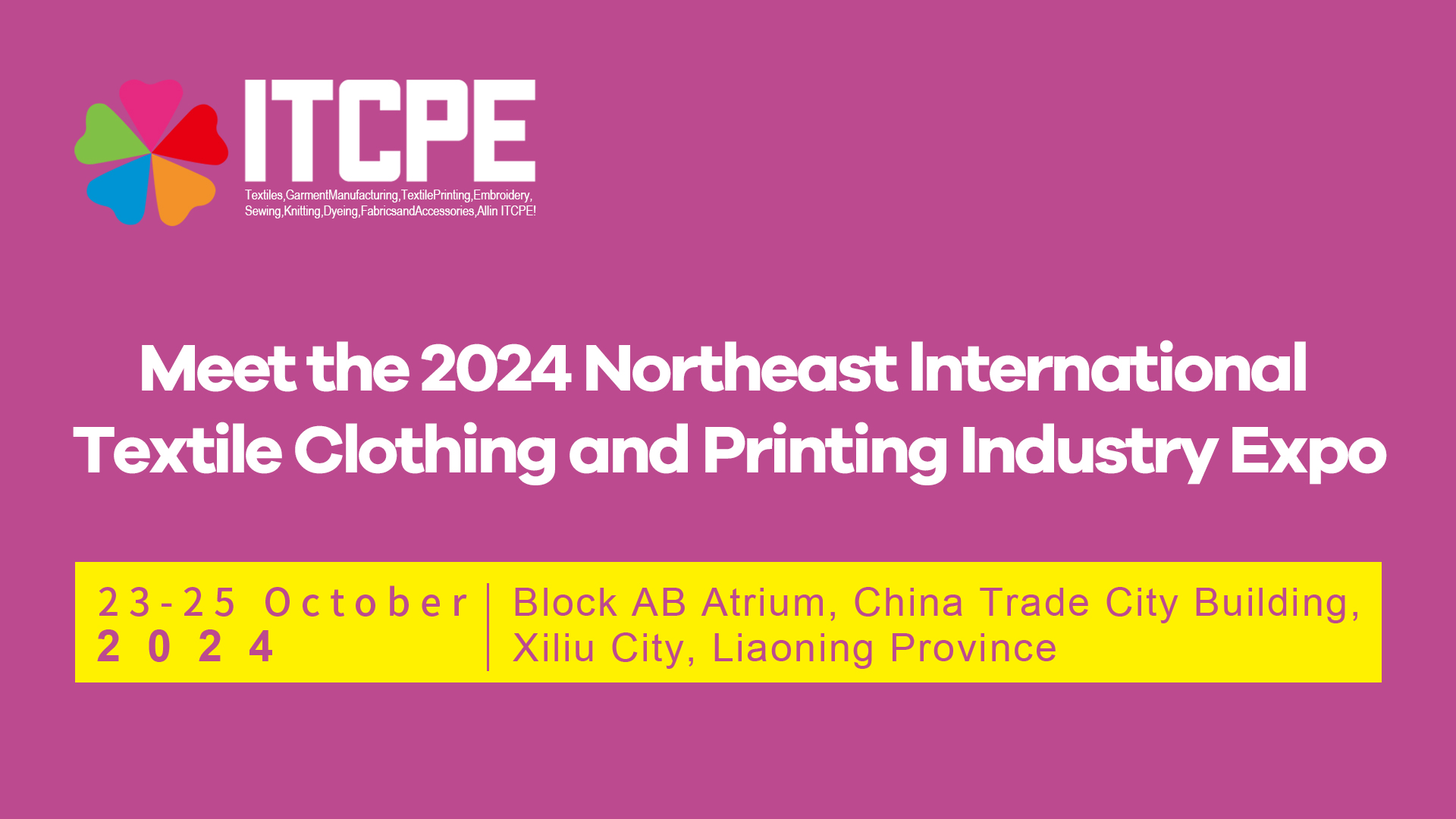

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967